Ford Powershift 6DCT450 Fault.

This job came to us from CAN Diagnostic. This TCM is fitted to a range of Ford and Volvo vehicles. There was an issue with the pump which meant it would be cheaper to clone the data to another replacement module.

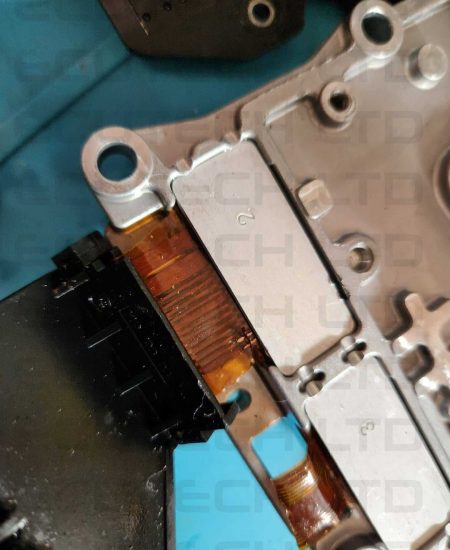

The issue with this for us was a ribbon cable was broken making communications with the module impossible and because of that it was also impossible to get any data read. The link wires were also broken off the PCB.

Ford Powershift 6DCT450 Fault

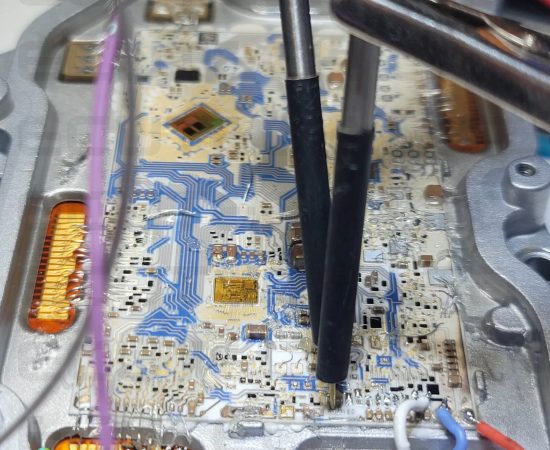

We set about exposing the naked PCB and having a good look at what we were working with.

These PCB’s are covered in gel from the factory and removing it is far from a straightforward process. Also, ally solder is used which again is a pain to work with.

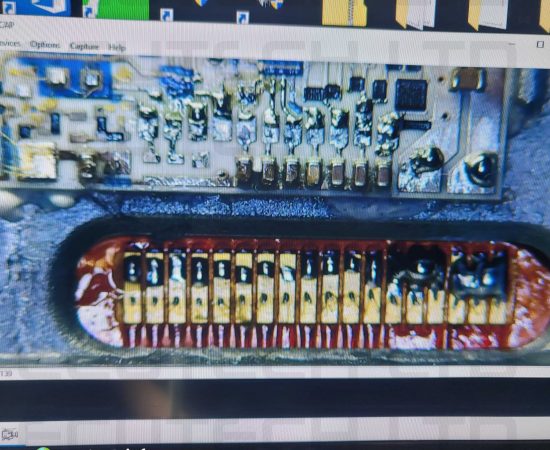

Next job was to expose the working area of the gel. This took a VERY long time to ensure all traces of gel were removed so we were able to solder some link wires to the PCB.

Next was to remove the original remaining link wires. These are about the thickness of a human hair!

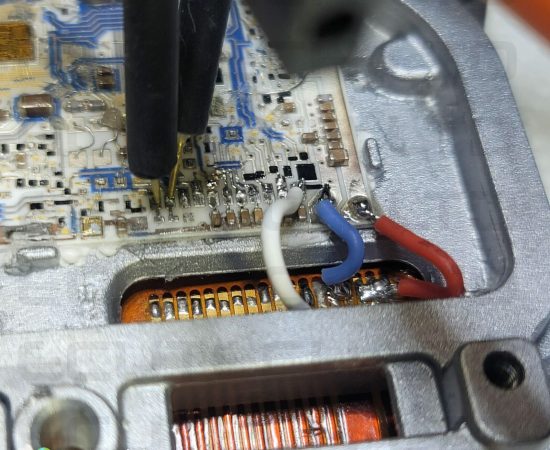

That done, we found a damaged CAN L track on the PCB. We exposed new track for the CAN L and used a pair of fine BDM probes on the CAN L and H tracks to establish data comms with the unit.

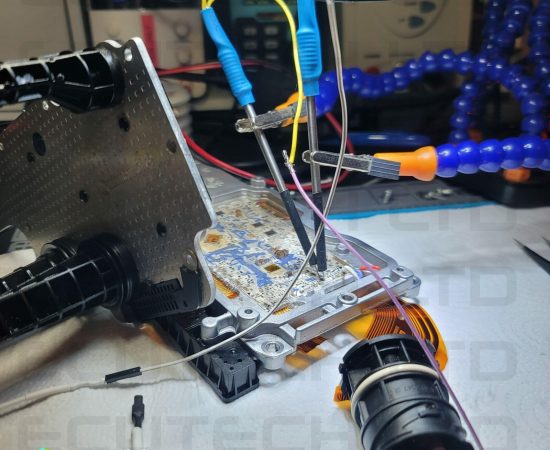

Next was to find a pinout of the PCB, solder some links for KL15, KL31 and KL30. This done, we applied power.

As a side note, at 12.1v these units draw 450ma if healthy with both KL30 and 15 active.

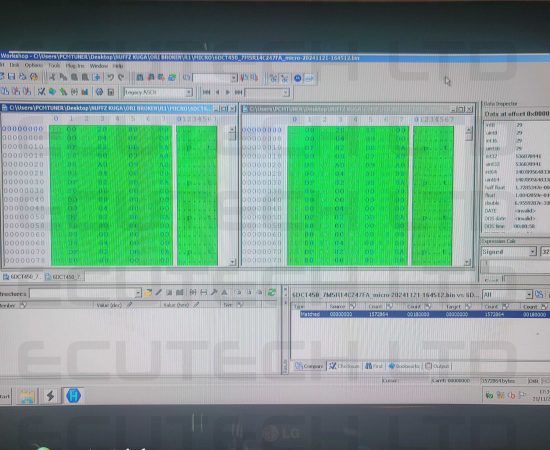

A full read of both MIcro and Eeprom were finally obtained!

After reading both Micro and Eeprom twice, we compared both reads to be certain the chips were in good health and not giving erroneous data. All was good so we were able to carry on to the next step.

Next was to connect to the replacement TCM, a straightforward 30 second job!

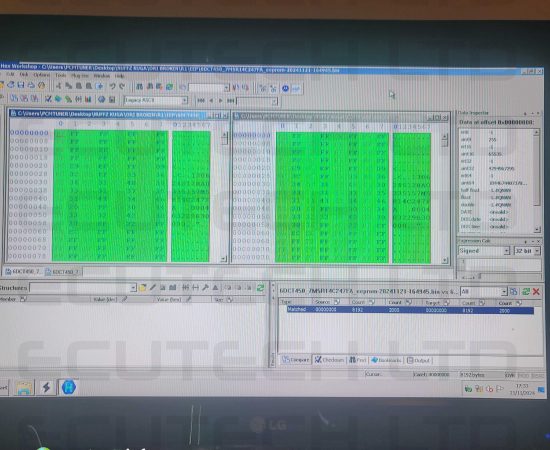

Then we made a backup of both Micro and Eeprom of the replacement TCM (just in case), then wrote the data from the original TCM to the Replacement TCM.

Finally, we comapred both Micro and Eeprom reads from the original tcm against the newly written to TCM to make 100% certain we had a full clone!

We did and finally this job was accomplished. It took the best part of 2 days, mostly time was spent prepping the damaged board and making good tracks.